Bridgestone debut a new tire mounting system which will be extended to its plants around the world. Human dependence is dwindling on the production side.

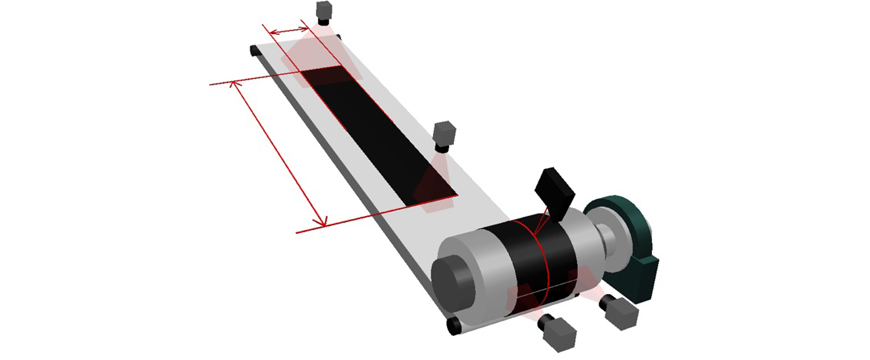

Bridgestone Corporation announced the integration of a new tire mounting system called the Hikone plant. Designed to improve the quality and enhance productivity in the production of tires, this system combines advanced information and communication technologies own Bridgestone artificial intelligence. Bridgestone plans to implement this system in all its existing plants in order to increase the competitiveness of the production side of operations and allow the Group to provide products with an even higher quality to a wide range of customers.

Bridgestone started its research and development of tire production systems, using ICT and other technologies tip at the end of the 1990s, in order to create more functional and top quality tires. In 2002, the company developed the Bird production system, which was the world pioneer in complete automation in various areas of production, from components to process product inspection processes. The system was also equipped to monitor the conditions of real-time manufacturing sites.

The Examination System incorporates the most advanced versions of information and communication technologies used in Bird system, and also employs new registered technology, and based on new concepts of Bridgestone Intelligent Office BIO and Bridgestone Intelligent Device IDB. BIO and IDB refer to technologies that incorporate data analysis based on experience Bridgestone central processing high polymers – rubber complex materials, which represent a central area of technology in the Group. These technologies also employ patented algorithms, which are made by combining the analysis of large volumes of data, collected in the manufacturing process, with the experience and technical experts in the Bridgestone manufacturing processes.

Being based algorithms that go beyond the knowledge acquired by BIO, the IDB has an artificial intelligence that automatically controls the production systems, and thus allows the automatic control of production processes and reviews and quality assurance procedures that were previously dependent on human skills. The system allows us to minimize disparities several of the production process and that arises from differences in human capabilities, enabling precision levels never before seen. Furthermore, the data collected by the system will be used together with the data existing tire assembly machinery, processes performed before and after assembly, products and other areas, in order to improve the quality of procedures in factories.

Learn more at www.bridgestone.pt

No comments:

Post a Comment